Lockout Hasps

Electric Power Isolation Insulation Hasps Lockouts BAN-K41/K42/K43Enhance electrical safety protocols with Electric Power Isolation Insulation Hasps Lockouts, available in vibrant red color for increased visibility. Crafted from durable plastic, these lockouts facilitate multi-worker lockout procedures, keeping equipment inoperative during maintenance or repairs. With spark-proof nylon construction and the capacity to accommodate up to 6 padlocks, these lockouts ensure comprehensive electrical i..

Add to CartSparkproof Aluminum Lockout Hasps BAN-K11Secure your equipment with confidence using Beian Lock Sparkproof Aluminum Lockout Hasps BAN-K11. Crafted from spark-resistant zinc aluminum alloy, these lockout hasps offer reliable protection in hazardous environments. With dimensions of 32x107x8mm and a weight of 55g, they provide a sturdy and durable solution for lockout/tagout procedures. The bright red color ensures high visibility, while the aluminum jaws provide a 25mm (1") clearance, allowing the..

Add to CartSteel Heavy Duty Lockout Hasp BAN-K321. Lockout by multiple workers at each lockout point.2. Control cannot be turned on until last worker'spadlock is removed from hasp.3. With 25mm(1") inside jaw diameter and 79mm height, holds up to 8 safety padlocks...

Add to CartSteel Lockout Hasp BAN-K01Enhance workplace safety with Beian Lock Steel Lockout Hasp BAN-K01. Crafted from durable steel, this lockout hasp provides reliable protection during maintenance or repair procedures. With dimensions of 40mm(L)x115mm(H)x10mm(W) and a weight of 104g, it offers a sturdy and secure solution for lockout/tagout applications. The vibrant red color ensures high visibility, while the 25mm(1") inside jaw diameter allows it to hold up to 6 safety padlocks. Designed for multi-wor..

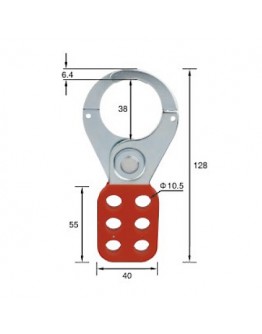

Add to CartSteel Lockout Hasp BAN-K02Ensure optimal safety during maintenance or repair tasks with Beian Lock Steel Lockout Hasp BAN-K02. Constructed from robust steel, this lockout hasp provides reliable protection by keeping equipment inoperative until all work is completed. With dimensions of 40mm(L)x128mm(H)x10mm(W) and a weight of 118g, it offers a sturdy solution for multi-worker lockout scenarios. The vibrant red color enhances visibility, while the 38mm(1.5") inside jaw diameter accommodates up to ..

Add to CartTen Holes Aluminum Safety Lockout Hasps BAN-K641. Red/Blue/Yellow three colors for selection.2. Red lockout hasp with tagout identification for multiple workers.3. Anodized aluminum and stainless steel construction for combined corrosion-resistance and strength.4. Complete with high visiblity,write-on safety labels in English.5. Holds up to 10 safety padlocks...

Add to CartAluminum Facility Safety Lockout Hasp Beian-Lock BAN-K25Ensure comprehensive lockout/tagout procedures with the Beian-Lock BAN-K25 Aluminum Facility Safety Lockout Hasp. Made from durable aluminum and finished in high-visibility red, this hasp allows up to 12 workers to lock out each lockout point. It keeps equipment inoperative during repairs or adjustments and isolates the energy source until the last worker's padlock is removed. The non-sparking, anodized aluminum finish provides superior cor..

Pre orderAluminum Safety Lockout Hasp with 24 Holes Beian-Lock BAN-K26Enhance workplace safety with the Beian-Lock BAN-K26 Aluminum Safety Lockout Hasp. Crafted from durable aluminum and finished in high-visibility red, this hasp allows up to 24 workers to lock out each lockout point. It keeps equipment inoperative during repairs or adjustments and isolates the energy source until the last worker's padlock is removed. The non-sparking, anodized aluminum finish provides superior corrosion resistance for l..

Pre orderDouble-End Aluminum Hasp BAN-K61Secure your equipment with the BAN-K61 Double-End Aluminum Hasp. Crafted from lightweight aluminum alloy with rust-treated surfaces, this hasp ensures durability and longevity. Featuring double ends of different sizes (38mm and 25mm), it offers versatility in locking various equipment. With the capacity to accommodate up to 8 padlocks, it provides enhanced security for your belongings.Improve Lockout Efficiency with BAN-K61 Double-End Aluminum HaspLightweight Alum..

Pre orderElectrical Safety Insulated Nylon Lockout Hasp BAN-K48Enhance electrical safety protocols with the BAN-K48 Electrical Safety Insulated Nylon Lockout Hasp, an improved version of the K41/K42/43 models. Crafted from durable nylon in a vibrant red color, this lightweight hasp offers improved portability and convenience for lockout/tagout procedures. Featuring a smaller size and spark-proof nylon construction, it holds up to 3 padlocks and includes an identification label for easy identification and..

Pre orderLabeled Lockout Hasp BAN-K65Enhance your lockout tagout procedures with the LABELED LOCKOUT HASP BAN-K65. This red lockout hasp features tagout identification for multiple workers, improving safety protocols in industrial settings. Its spring-loaded locking arm offers an easy-to-apply 'snap-on' advantage, ensuring efficient operation during lockout procedures. Constructed from anodized aluminum and stainless steel, this hasp provides corrosion resistance and durability for long-term use. It fits..

Pre orderThe lockout hasp is essential in any successful security locksout program, as it is advisable to have multiple persons lockouts. Multiple padlocks are available in Lockout Hasps to enable the isolation of energy from other employees. The power source will not run until all workers unlock the hasp and the padlocks are removed. Lockout - Hasps attach to different sections of hazardous energy sources to ensure they cannot be tagged visually.

Lockout/Tagout (LOTO) is a safety procedure used to secure energy sources and prevent the accidental activation of equipment during maintenance or repair work. One of the key components of LOTO is the use of lockout hasps, which play a crucial role in securing energy sources and ensuring the safety of workers.

A lockout hasp is a metal or plastic bracket that is attached to an energy source, such as an electrical panel or machine. The hasp allows multiple workers to lock out the energy source, making it impossible to turn on until all locks have been removed. This helps to ensure that no one can accidentally or intentionally activate the energy source while maintenance or repair work is being performed.

There are different types of lockout hasps available, including individual, group, and adjustable hasps. The type of hasp used will depend on the specific energy source and the number of workers who will be performing maintenance or repair work.

In addition to the use of lockout hasps, it is important to follow proper LOTO procedures and to train workers on their proper use. This includes identifying all energy sources that need to be locked out, properly tagging the energy sources, and ensuring that all workers understand the procedures for locking out the energy source and removing the locks.

It is also important to regularly inspect and maintain lockout hasps to ensure that they are in good condition and functioning properly. If a hasp becomes damaged or worn, it should be replaced as soon as possible to ensure continued safety.

LOTO is a comprehensive safety program that also includes the use of personal protective equipment, such as gloves and safety glasses, and proper training and safety procedures. By implementing LOTO and using lockout hasps, employers can help to create a safe working environment and minimize the risk of injury or equipment damage.

And lockout hasps play a critical role in the LOTO safety procedure. They help to secure energy sources and ensure the safety of workers during maintenance or repair work. By using lockout hasps, following proper LOTO procedures, and implementing other safety measures, employers can help to create a safe working environment and minimize the risk of injury or equipment damage.

.png)