Blog

Lock Out Tag Out Safety Training Videos PPTs Online Courses

Get the best lock out tag out safety training with our comprehensive range of videos, PPTs, online courses and more. Learn about requirements, materials and boards for free. Get trained in Toronto today.

Lock Out Tag Out Training - What You Need to Know

Learn about lock out tag out training requirements, including OSHA regulations, certificate template and PowerPoint presentation. Get the information you need to ensure your workplace is following the necessary safety protocols.

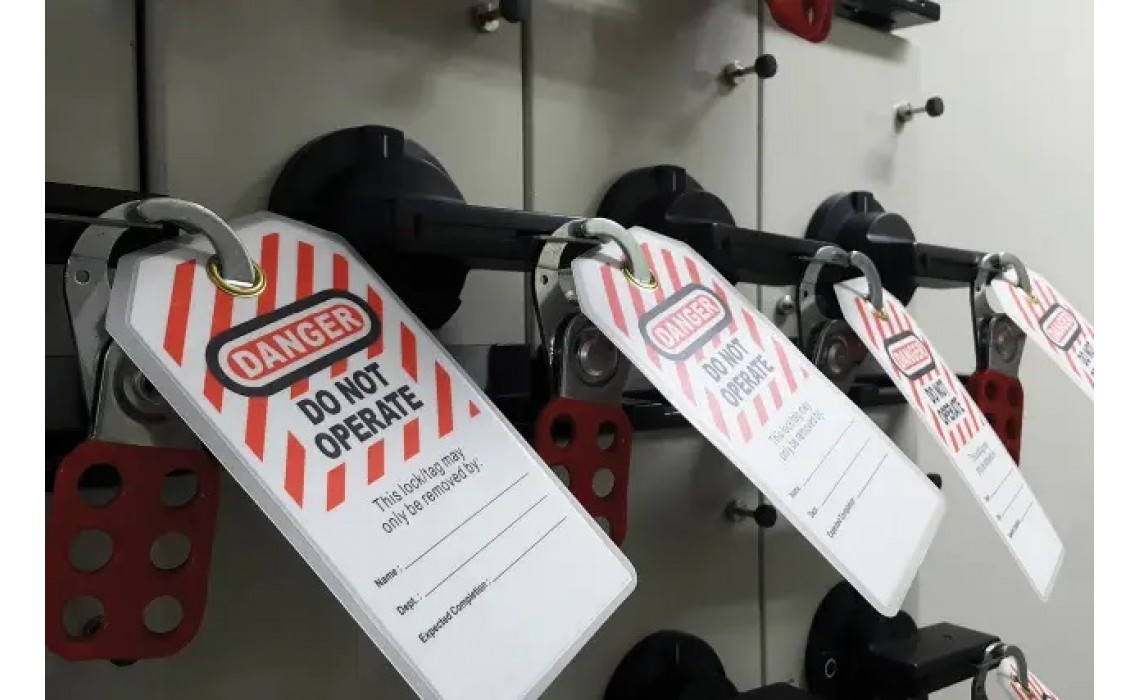

Lock Out Tag Out Kits - Find the Ideal Kit for Your Electrical Needs

Shop for the ideal lock out tag out kit for your electrical needs. We offer a variety of lock out tag out kits to fit your needs, including circuit breaker lock out tag out kits, wall mount kits, and more. Shop now and find the perfect kit near you.

Everything You Need to Know About Lock Out Tag Out Procedures

Understand the importance of lock out tag out procedures and learn how to implement them in your workplace. Get a free template, checklist & PDF to help you get started.

What Equipment Requires a Lockout-Tagout Procedure?

In order to be lockout-tagout compliant according to the OSHA standard 1910.147, Control of Hazardous Energy, there are five components that must be met. The five components consist of a corporate policy, lockout-tagout locks and devices, annual inspection of employees and procedures, authorized and affected training, and machine specific lockout-tagout procedures.

-1140x700.png)

.png)