Lock Out Tag Out Safety Training Videos PPTs Online Courses

What is Lock Out Tag Out Training?

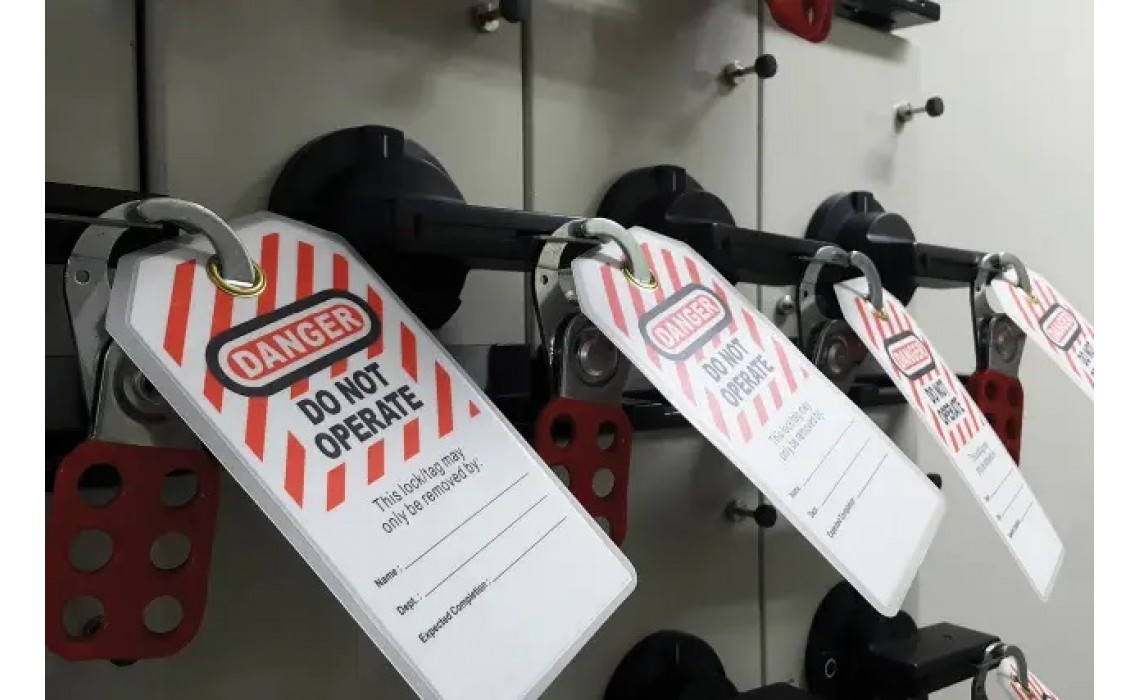

Lock Out Tag Out (LOTO) is a safety procedure used to prevent accidents in the workplace by ensuring the safe isolation of hazardous energy sources. It is a method of controlling hazardous energy through the use of locks, tags, and other safety devices. The purpose of LOTO is to ensure that all personnel are aware of the potential dangers associated with working on or near energized equipment and that proper safety precautions are taken before any work can be conducted. LOTO training provides employees with the knowledge and skills necessary to safely conduct their work activities while protecting themselves and others from potential hazards.

Why Is Lock Out Tag Out Training Important?

Lock out tag out training is an important part of any workplace safety program. It ensures that all personnel understand the risks associated with working on or near energized equipment and that proper safety precautions are taken before any work can be conducted. This type of training helps to reduce the risk of injury or death due to electrical shock or other types of accidents involving hazardous energy sources. Additionally, LOTO training helps to ensure that all personnel understand how to properly use locks, tags, and other safety devices in order to protect themselves and others from potential hazards.

What Are The Benefits Of Lock Out Tag Out Training?

The benefits of lock out tag out training include improved workplace safety, reduced risk of injury or death due to electrical shock or other types of accidents involving hazardous energy sources, increased awareness among employees about potential risks associated with working on energized equipment, improved productivity due to fewer delays caused by accidents, and cost savings due to reduced downtime resulting from accidents. Additionally, this type of training helps ensure that all personnel understand how to properly use locks, tags, and other safety devices in order to protect themselves and others from potential hazards.

What Should Be Included In Lock Out Tag Out Training?

Lock out tag out training should include an overview of the purpose and importance of LOTO procedures as well as instruction on how to properly use locks, tags, and other safety devices. Additionally, it should cover topics such as identifying hazardous energy sources; assessing risks; selecting appropriate lockout/tagout devices; establishing a lockout/tagout procedure; implementing lockout/tagout procedures; testing equipment after lockout/tagout; releasing lockout/tagout devices; inspecting equipment after release; recording information related to lockout/tagout activities; and providing refresher courses for personnel who have had previous lock out tag out training.

How Can You Get Access To A Lock Out Tag Out Training Video?

There are many online resources available for those looking for access to a lock out tag out training video. Many employers provide their own videos as part of their employee safety programs. Additionally, there are many websites offering free videos or videos for purchase that provide comprehensive instruction on LOTO procedures. Finally, there are also professional organizations that offer certification courses which include access to a lock out tag out training video as part of their curriculum.

Lockout Tagout Training PPT: Benefits and Best Practices

Lockout tagout (LOTO) is a safety procedure used to prevent accidental or unauthorized access to hazardous energy sources, such as electricity, gas, and steam. The purpose of LOTO is to ensure that personnel are not exposed to hazardous energy during maintenance or repair activities. To ensure that the procedure is followed correctly and safely, it is important for all personnel to receive proper training in the form of a Lockout Tagout Training PPT.

What are the Benefits of Lockout Tagout Training PPT?

There are many benefits of using a Lockout Tagout Training PPT. First, it ensures that personnel understand the risks associated with working on machinery and systems with hazardous energy sources. It also helps personnel understand how to properly use lockout tagout devices, such as circuit breakers and padlocks. Additionally, a Lockout Tagout Training PPT can help personnel identify potential hazards in their work environment and take steps to reduce those risks. Finally, it can help personnel understand their responsibilities when it comes to following LOTO procedures in order to protect themselves and others from harm.

What are the Best Practices for Lockout Tagout Training?

When designing a Lockout Tagout Training PPT, there are several best practices that should be followed. First, it should include information about the purpose of LOTO and its importance in protecting personnel from harm. Additionally, it should explain how lockout tagouts work and provide examples of different types of lockout tagouts devices that can be used. Finally, the presentation should provide guidance on how to properly use these devices and explain what steps must be taken if an emergency situation arises while using them.

How Can I Ensure My Personnel Receive Effective Lock Out Tag Out Training?

To ensure that your personnel receive effective Lock Out Tag Out training using a PPT presentation, there are several steps you can take. First, you should make sure that your presentation is clear and easy to follow by including visuals such as diagrams or photographs whenever possible. Additionally, you should provide practical examples of how lockout tagouts work so that your personnel can better understand the concepts they are learning about. Finally, you should always make sure your presentation includes up-to-date information about LOTO regulations so that your personnel will know what they need to do when working with hazardous energy sources.

What Topics Are Covered in Online Lock Out Tag Out Training?

Online Lock Out Tag Out (LOTO) training covers a wide range of topics related to safety protocols and best practices when dealing with hazardous energy sources. These topics include understanding OSHA regulations regarding LOTO, identifying different types of hazardous energy sources, understanding lockout/tagout devices and procedures, recognizing common hazards associated with LOTO, knowing when it’s safe to begin work after a lockout/tagout procedure has been completed, and more. Additionally, some online LOTO courses also cover additional topics such as machine guarding and personal protective equipment (PPE).

Who Can Benefit From Online Lockout Tagout Training?

Online Lockout Tagout (LOTO) training can benefit anyone who works in an industry where hazardous energy sources are present. This includes manufacturing plants, construction sites, power plants, automotive repair shops, oil refineries, chemical plants, and many more. By providing this type of training to their employees, employers can help to reduce the risk of injury or death due to an accident involving hazardous energy sources. Additionally, it helps ensure that all workers understand the importance of following safety protocols when working on or near equipment that has been locked out or tagged out. Online lock out tag out training is essential for any industry where hazardous energy sources are present as it helps protect both employees and employers from potential accidents caused by improper use of lockouts/tags outs devices and procedures.

How Can Employers Provide Online Lockout Tagout Training?

Employers can provide online Lockout Tagout (LOTO)training through various methods such as online courses offered by third-party providers or they can create their own custom courses using tools such as video tutorials or interactive simulations. Employers should also consider offering periodic refresher courses for their employees as well as making sure all employees have access to up-to-date materials related to LOTO regulations and best practices so they remain informed about any changes in laws or regulations regarding lockouts/tags outs devices and procedures.

What Are the Benefits of Lock Out Tag Out Training Online?

There are many benefits associated with lock out tag out training online. It can be completed at any time, which makes it convenient for busy workers who may not have time for traditional classroom-based learning. Additionally, online courses can be tailored to meet specific needs, allowing employers to provide their employees with targeted instruction on how best to use LOTO in their particular workplace situation. Furthermore, online courses are often more cost-effective than traditional classroom-based instruction, making them an attractive option for businesses looking for ways to save money while still providing quality safety training for their employees.

What Should Be Included in Lock Out Tag Out Training Online?

A good lock out tag out training online program should cover a range of topics related to LOTO safety procedures. These may include information on identifying hazardous energy sources, proper lockout/tagout procedures, safe handling practices when working with machinery, as well as tips on how best to protect oneself from potential hazards associated with lockout/tagout situations. Additionally, the course should include real-world examples of how these procedures have been successfully implemented in various workplaces so that students can gain a better understanding of what they need to do in order to keep themselves and others safe while working with hazardous equipment.

How Can Employers Ensure Their Employees Receive Quality Lock Out Tag Out Training Online?

Employers should look for lock out tag out training programs that are accredited by reputable organizations such as OSHA or NSC (National Safety Council). Additionally, employers should ensure that the program they choose covers all relevant topics related to LOTO safety and includes real-world examples so that students can gain a better understanding of what they need to do in order to keep themselves and others safe while working with hazardous equipment. Finally, employers should look for programs that offer support after completion so that employees can continue learning about lockout/tagout safety even after they have completed their coursework.

Free Lock Out Tag Out Training: What You Need to Know

Lock out tag out (LOTO) is a safety procedure used to protect workers from the risks of hazardous energy sources. It requires locking and tagging machines and equipment before any maintenance or repair work is done. To ensure that the LOTO process is properly followed, workers must receive free lock out tag out training. This training covers the fundamentals of LOTO and provides practical guidance on how to safely lock and tag equipment.

Why Is Lock Out Tag Out Training Important?

LOTO training is essential for any worker who needs to work on potentially hazardous machines or equipment. Without proper training, workers may not know how to properly lock and tag the equipment, which can lead to dangerous situations. Additionally, LOTO training helps workers understand the importance of following safety protocols and the consequences of not doing so.

What Is Covered in Lock Out Tag Out Training?

Free lock out tag out training typically covers a range of topics, including:

- Identifying hazardous energy sources

- Understanding different types of locks and tags

- Properly isolating hazardous energy sources

- Developing lockout/tagout procedures

- Testing lockout/tagout devices

- Developing control measures for residual energy sources

Trainees should also be taught about common mistakes associated with LOTO procedures, such as failing to test lockout devices after installation or neglecting to inspect them periodically. The trainer should also discuss the importance of documenting all lockout/tagout activities in a logbook.

Where Can I Find Free Lock Out Tag Out Training?

There are a variety of resources available for free lock out tag out training, including online courses and in-person workshops. Many employers provide free LOTO training for their employees, so it’s important to check with your employer first if you need this type of training. Additionally, many professional organizations offer free online courses on LOTO safety protocols. These courses typically include videos, quizzes, and other interactive elements to help trainees understand the material better. Finally, there are several books available on the subject that can be used as reference materials during or after a course or workshop.

Lock Out Tag Out Training Toronto: What You Need To Know

Lock Out Tag Out (LOTO) is a safety procedure used in industrial settings to prevent the unexpected start-up or release of hazardous energy during maintenance and servicing activities. It is an important part of any workplace safety program, and in Toronto, it is essential for employers to ensure their workers are properly trained in LOTO. This article will outline what you need to know about Lock Out Tag Out training Toronto and the importance of such training.

Where Can I Find Lockout/Tagout Training in Toronto?

There are a number of organizations in Toronto that provide lockout/tagout training courses for employers and employees alike. These organizations typically offer courses ranging from basic awareness level courses up through advanced lockout/tagout certification programs for those who wish to become certified in this area. Some organizations also offer online courses so that employees can take their trainings from anywhere at any time.

Lock out tag out training Toronto is an essential part of any workplace safety program. Without proper training on how to safely control hazardous energy sources using locks, tags, and other devices, workers may be exposed to serious hazards that could lead to injury or death if not addressed immediately. Employers should ensure their workers receive proper LOTO instruction so they can work safely and effectively while protecting themselves from potential harm

What is Lock Out Tag Out Training Board?

Lock out tag out training board is a safety system used to protect workers from hazardous machinery. It is designed to prevent machines from being accidentally activated and causing injury or death. The lock out tag out system consists of a board with tags that are placed on machines when they are not in use, and locks that are placed on the machine when it is in use. This ensures that only authorized personnel can operate the machine and that all safety protocols are followed. Lock out tag out training board is an important part of any workplace safety program and should be implemented in all workplaces.

Why Is Lock Out Tag Out Training Board Necessary?

Accidents involving hazardous machinery can have serious consequences for workers, including death or serious injury. The lock out tag out training board helps to ensure that only authorized personnel can operate the machine, and that all safety protocols are followed. This reduces the risk of accidents and ensures a safe working environment for everyone. In addition, it also helps to reduce costs associated with workplace injuries, as there will be fewer incidents requiring medical attention or time off work.

What Are The Benefits Of Lock Out Tag Out Training Board?

The main benefit of using a lock out tag out training board is that it helps to ensure the safety of workers by preventing unauthorized use of hazardous machinery. It also reduces costs associated with workplace injuries, as there will be fewer incidents requiring medical attention or time off work. Additionally, it can help to increase productivity by reducing downtime due to accidents or malfunctions caused by unauthorized personnel operating the machine. Finally, it can help to improve morale among employees as they feel more secure knowing their workplace is safe and secure.

How To Implement Lock Out Tag Out Training Board?

The first step in implementing a lock out tag out training board is to identify which machines need to be locked out and tagged when not in use. Once these machines have been identified, locks should be placed on them so that only authorized personnel can access them when needed. Additionally, tags should be placed on each machine so that they are clearly visible when not in use and so that they cannot be easily removed by unauthorized personnel. Finally, employees should receive regular training on how to correctly use the lock out tagout system so that they understand its importance and how it works.

What is Lock Out Tag Out Training Material?

Lock out tag out (LOTO) is a safety procedure used in industry and research settings to ensure that dangerous machines are properly shut off and not able to be started up again prior to the completion of maintenance or servicing work. Lock out tag out training material is designed to provide workers with the knowledge and skills they need to properly use LOTO in their workplace. The material covers topics such as the purpose of LOTO, proper lockout/tagout procedures, and safety precautions when using LOTO.

What Should be Included in Lock Out Tag Out Training Material?

Lock out tag out training material should include information on the purpose of LOTO, proper lockout/tagout procedures, and safety precautions when using LOTO. The material should also cover how to identify hazardous energy sources, how to control hazardous energy sources, how to install locks and tags, and how to inspect locked-out equipment. Additionally, the material should include steps for removing locks and tags once maintenance or servicing work has been completed.

How Can Employers Ensure That Workers Receive Proper Lock Out Tag Out Training?

Employers can ensure that workers receive proper lock out tag out training by providing clear written instructions on lockout/tagout procedures and making sure that all workers are trained on these procedures before they begin working with any potentially hazardous equipment. Additionally, employers should conduct regular refresher courses for all employees who use lock-out/tag-out devices as part of their job duties. Finally, employers should keep a record of all employees who have received lock-out/tag-out training so that they can easily verify which employees have received this important safety instruction.

What Are Lockout Tagout Training Requirements?

Lockout tagout (LOTO) training is a critical requirement for any workplace that involves the use of hazardous energy sources. It is essential for employers to provide their employees with adequate instruction and education on how to safely control hazardous energy sources in their workplace. LOTO training requirements are mandated by the Occupational Safety and Health Administration (OSHA). This training is designed to help employers protect their workers from injury or death due to hazardous energy exposure.

How Can Employers Ensure Compliance With Lock Out Tag Out Training Requirements?

In order for employers to ensure compliance with lockout tagout (LOTO) training requirements, they must provide their staff with comprehensive instruction on how to safely control hazardous energies in their workplace. Additionally, employers should also create policies and procedures that outline specific safety protocols for handling these energies. Having clear policies in place will help ensure that all employees understand what is expected of them when it comes to controlling these dangerous energies and will help reduce the risk of accidents occurring due to improper use or handling.

What is Lock Out Tag Out Safety Training?

Lock out tag out safety training is a type of safety training that focuses on preventing injuries and fatalities in the workplace by teaching employees how to properly lock out and tag out energy sources. The goal of this training is to ensure that all employees are aware of the potential hazards associated with energy sources and how to properly control them. Lock out tag out safety training helps workers understand the importance of following safety procedures, as well as the necessary steps they should take when working with or near energy sources. Lock out tag out safety training can help reduce risks of serious injury or death in the workplace.

What Does Lock Out Tag Out Safety Training Include?

Lockout tagout safety training typically includes instruction on identifying hazardous energy sources, understanding the potential risks associated with them, and learning how to properly control them using lockout tags and other devices. The course also covers topics such as proper lockout/tagout procedure, equipment inspection requirements, testing methods for checking equipment for hazardous conditions, and emergency shutoff procedures. Additionally, lockout tagout safety training may include instruction on personal protective equipment (PPE) use when working around hazardous energy sources.

Who Should Take Lock Out Tag Out Safety Training?

Any employee who works with or near hazardous energy sources should take lockout/tagout safety training in order to reduce their risk of injury or death while on the job. This includes electricians, engineers, maintenance personnel, production workers, facility managers, supervisors and other personnel who work in industries where there are potential hazards from electrical currents or other forms of energized machinery or equipment. Additionally, any employee who performs duties such as cleaning up after an accident involving a hazardous source should take lock out tag out safety training.

Where Can Employees Get Lock Out Tag Out Safety Training?

Employees can get lockout/tagout safety training from their employer or from a third-party provider such as a trade school or technical college. Online courses are also available for those who prefer self-study or need more flexibility when it comes to completing their lock out tag out safety training. It’s important for employers to ensure that all employees receive proper lock out/tag out safety instruction before allowing them to work with energized machinery or equipment in order to reduce risks of injury or death in the workplace.

Related products

Sparkproof Aluminum Lockout Hasps BAN-K11Secure your equipment with confidence using Beian Lock Sparkproof Aluminum Lockout Hasps BAN-K11. Crafted from spark-resistant zinc aluminum alloy, these lockout hasps offer reliable protection in hazardous environments. With dimensions of 32x107x8mm and a weight of 55g, they provide a sturdy and durable solution for lockout/tagout procedures. The bright red color ensures high visibility, while the aluminum jaws provide a 25mm (1") clearance, allowing them to hold up to 6 padlocks simultaneously. Each lockout point can be controlled by multiple workers, and the equipment cannot be turned on until the last worker's safety padlock is removed from the hasp, ensuring maximum safety in the workplace.Reliable and Safe Lockout Solution for Hazardous EnvironmentsSpark-Resistant Construction: Made from high-quality zinc aluminum alloy, these lockout hasps are spark resistant, making them suitable for use in hazardous environments.Durable and Sturdy: With dimensions of 32x107x8mm and a weight of 55g, these lockout hasps provide a sturdy and durable solution for securing equipment during maintenance or repair.High Visibility: The bright red color ensures high visibility, allowing for easy identification and enhancing safety awareness in the workplace.Multiple Lockout Points: Each lockout hasp can accommodate up to 6 padlocks, allowing multiple workers to lock out equipment simultaneously.Controlled Lockout: The equipment cannot be turned on until the last worker's safety padlock is removed from the hasp, ensuring maximum safety during maintenance or repair procedures.Wide Clearance: Aluminum jaws provide a 25mm (1") clearance, accommodating a wide range of lockout devices and accessories.Easy to Use: Simple and straightforward operation, allowing for quick and efficient lockout/tagout procedures.Versatile Application: Suitable for use in various industrial, commercial, and residential settings to secure machinery, equipment, and electrical systems.Compliance: Complies with safety standards and regulations for lockout/tagout procedures, ensuring workplace safety and compliance.Compact Design: Compact and portable design allows for easy storage and transportation between different lockout points...

Add to CartSteel Heavy Duty Lockout Hasp BAN-K321. Lockout by multiple workers at each lockout point.2. Control cannot be turned on until last worker'spadlock is removed from hasp.3. With 25mm(1") inside jaw diameter and 79mm height, holds up to 8 safety padlocks...

Add to CartElectric Power Isolation Insulation Hasps Lockouts BAN-K41/K42/K43Enhance electrical safety protocols with Electric Power Isolation Insulation Hasps Lockouts, available in vibrant red color for increased visibility. Crafted from durable plastic, these lockouts facilitate multi-worker lockout procedures, keeping equipment inoperative during maintenance or repairs. With spark-proof nylon construction and the capacity to accommodate up to 6 padlocks, these lockouts ensure comprehensive electrical isolation for enhanced workplace safety.Ensure Electrical Safety with BAN-K41/K42/K43 Electric Power Isolation Insulation Hasps LockoutsMulti-Worker Lockout Capability: Designed to facilitate lockout procedures by multiple workers at each lockout point, these insulation hasps enhance workplace safety protocols by ensuring collaborative equipment isolation during maintenance or repair tasks.Durable Plastic Construction: Crafted from high-quality plastic material, these lockouts offer durability and longevity, withstanding frequent use and harsh environmental conditions for reliable performance in industrial settings.Vibrant Red Color: Featuring a vibrant red color, these lockouts provide increased visibility, making it easy to identify and locate lockout points within the facility, even from a distance, for enhanced safety awareness.Equipment Inoperability Assurance: Securely lockout electrical equipment to prevent accidental activation or operation during repair or adjustment procedures, ensuring the safety of maintenance personnel and preventing potential accidents or injuries.Spark-Proof Nylon Construction: Constructed from spark-proof nylon material, these lockouts offer additional safety measures, reducing the risk of electrical hazards and ensuring compliance with safety regulations and standards.Accommodates Multiple Padlocks: With the capacity to hold up to 6 padlocks, these insulation hasps provide versatile lockout options, allowing for secure isolation of equipment with multiple access points or by multiple workers simultaneously.Easy-to-Use Design: Featuring a user-friendly design, these lockouts are easy to install and remove, streamlining the lockout process and minimizing downtime during maintenance or repair operations.Suitable for Various Applications: Ideal for use in industrial facilities, manufacturing plants, commercial buildings, and other workplaces with electrical equipment, these lockouts offer versatile lockout solutions for comprehensive electrical isolation and safety.Compliance with Safety Standards: Ensure compliance with safety regulations and standards by incorporating these insulation hasps into your lockout/tagout procedures, providing a reliable and effective means of electrical isolation for maintenance and repair activities. BAN-K41 BAN-K42 BAN-K43Usage:BAN-K41BAN-K42BAN-K43..

Add to CartSteel Lockout Hasp BAN-K01Enhance workplace safety with Beian Lock Steel Lockout Hasp BAN-K01. Crafted from durable steel, this lockout hasp provides reliable protection during maintenance or repair procedures. With dimensions of 40mm(L)x115mm(H)x10mm(W) and a weight of 104g, it offers a sturdy and secure solution for lockout/tagout applications. The vibrant red color ensures high visibility, while the 25mm(1") inside jaw diameter allows it to hold up to 6 safety padlocks. Designed for multi-worker lockout scenarios, this hasp ensures that equipment remains inoperative until all workers have completed their tasks and removed their padlocks, promoting workplace safety and compliance.Durable and Secure Lockout Device for Industrial SafetyDurable Steel Construction: Made from high-quality steel, this lockout hasp offers strength and durability for long-lasting use in industrial environments.Secure Lockout: Lockout by multiple workers at each lockout point, ensuring that equipment remains inoperative while repairs or adjustments are being made.Enhanced Safety: Prevents unauthorized operation of equipment by ensuring that control cannot be turned on until the last worker's safety padlock is removed from the hasp.High Visibility: Vibrant red color provides high visibility, allowing for easy identification and enhancing safety awareness in the workplace.Generous Capacity: With a 25mm(1") inside jaw diameter, this hasp can hold up to 6 safety padlocks, accommodating multiple lockout devices simultaneously.Compact and Portable: Compact dimensions (40mm(L)x115mm(H)x10mm(W)) and lightweight design (104g) make it easy to store and transport between different lockout points.Versatile Application: Suitable for a wide range of industrial, commercial, and residential settings to secure machinery, equipment, and electrical systems during maintenance or repair procedures.Compliance: Complies with safety standards and regulations for lockout/tagout procedures, ensuring workplace safety and regulatory compliance.Easy to Use: Simple and straightforward operation, allowing for quick and efficient lockout/tagout procedures with minimal training required.Multipurpose Design: Can be used with a variety of lockout devices, including safety padlocks, lockout tags, and lockout cables, providing versatility and flexibility in lockout applications...

Add to Cart

.png)