Lock Out Tag Out Training - What You Need to Know

What is Lock Out Tag Out Training?

Lock out tag out training (LOTO) is a safety procedure used in many industries to prevent accidents and injury. It involves isolating hazardous energy sources from equipment or machinery before any work is done on it. The process includes locking and tagging the energy source, so that it cannot be accessed until the work is completed. LOTO training teaches employees how to properly identify, control, and manage hazardous energy sources in their workplace. Lock out tag out training helps employers ensure that their employees are aware of the risks associated with working on hazardous equipment and are trained to protect themselves from potential harm.

Why is Lock Out Tag Out Training Necessary?

Hazardous energy sources can cause serious injury or death if not properly managed. For this reason, it is important for employers to provide their employees with lock out tag out training. This type of training provides employees with the knowledge and skills needed to safely isolate hazardous energy sources before beginning any work on equipment or machinery. It also helps ensure that all workers understand the hazards associated with working on hazardous equipment and how to protect themselves from potential harm.

What Does Lock Out Tag Out Training Cover?

The purpose of lock out tag out training is to teach employees how to properly identify, control, and manage hazardous energy sources in their workplace. This type of training typically covers topics such as: identifying different types of hazardous energy sources; recognizing potential hazards associated with working on hazardous equipment; understanding applicable safety regulations; learning proper lock-out/tag-out procedures; understanding proper lockout/tag-out devices and how to use them correctly; learning appropriate inspection techniques for lockout/tag-out devices; understanding appropriate recordkeeping requirements for lock-out/tag-out procedures; and understanding emergency response procedures for dealing with unexpected releases of hazardous energy.

Who Should Receive Lock Out Tag Out Training?

All employees who may be exposed to hazardous energy sources should receive lock out tag out training. This includes anyone who works with or around machines or equipment that may contain potentially dangerous levels of electrical, hydraulic, pneumatic, chemical, thermal, or mechanical power. In addition, supervisors should also receive this type of training so they can ensure that their employees are following proper safety protocols when working around these types of machines or equipment.

Benefits of Lock Out Tag Out Training

The primary benefit of lock out tag out training is improved safety in the workplace. By teaching employees how to properly identify, control, and manage hazardous energy sources in their workplace they can reduce the risk of accidents or injury due to improper handling of these types of materials. In addition, providing this type of training can help employers comply with applicable safety regulations which can help avoid costly fines or other penalties due to noncompliance. Finally, providing this type of training can help increase employee morale by showing them that their employer cares about their safety which can lead to improved productivity in the workplace overall.

What is Lockout Tagout Training?

Lockout tagout training, also known as LOTO, is a safety procedure that is used in industrial settings to prevent the accidental start up of machinery or equipment. It involves the use of locks and tags to secure energy sources and prevent them from being accessed by unauthorized personnel. This type of training is essential for workers in any industry that involves hazardous energy sources, such as electricity, steam, or pressurized fluids. Lockout tagout training teaches workers how to effectively and safely control hazardous energy sources in order to protect themselves and their coworkers from potential injury or death.

Why is Lockout Tagout Training Necessary?

The purpose of lockout tagout training is to ensure that workers understand the risks associated with working with hazardous energy sources and how to properly control them. Without this type of training, workers may be unaware of the dangers posed by these sources and may not take the necessary precautions when working with them. This can lead to serious injuries or even death if a worker were to accidentally start up a machine or equipment without first properly locking out its energy source.

What Does Lockout Tagout Training Entail?

Lockout tagout training includes instruction on how to identify hazardous energy sources, how to control them using locks and tags, how to verify that they have been locked out correctly, and what steps should be taken if an emergency situation arises. The training also covers proper lockout tagout procedures for specific types of machinery and equipment as well as information on any special requirements for particular types of work environments. Additionally, it provides information on record keeping practices related to lockout tagouts as well as any applicable laws or regulations that must be followed when performing lockout tagouts in certain industries.

Who Needs Lockout Tagout Training?

Anyone who works with hazardous energy sources should receive lockout tagout training prior to beginning work on any machinery or equipment that has an energized source. This includes employees who are responsible for performing maintenance or repairs on machines or equipment as well as those who are responsible for controlling the energized source itself. Additionally, employers should provide periodic refresher courses in order for employees to stay up-to-date on any changes in safety procedures related to lockout tagouts.

Where Can I Find Lock Out Tag Out Training?

Lock out tag out training can be found through many different organizations such as trade unions, professional associations, safety organizations, schools and universities, government agencies, online courses providers and private companies offering specialized services related to safety compliance. It is important for employers to ensure that their workers receive proper lockout tag out training so that they can work safely around hazardous energy sources without putting themselves or their coworkers at risk of injury or death due to an accidental start up of a machine or equipment due lack of knowledge about proper safety procedures.

What is Lockout/Tagout Training?

Lockout/Tagout (LOTO) training is an important safety measure designed to protect workers from the dangers of hazardous energy sources. It is a system of procedures, practices, and equipment used to prevent the unexpected energization or start-up of machinery and equipment during maintenance or servicing activities. Lockout/Tagout training teaches workers how to properly identify, control, and isolate hazardous energy sources. This training is required by the Occupational Safety and Health Administration (OSHA) for all employees who work on or near hazardous energy sources.

Why Is Lockout/Tagout Training Important?

Lockout/Tagout training is essential for workplace safety. It helps ensure that workers are aware of the potential hazards associated with working on or near hazardous energy sources and how to safely control these sources. Without proper training, workers may not recognize the dangers posed by these sources or know how to properly protect themselves from them. Additionally, lockout/tagout procedures help reduce the risk of injury or death due to unexpected energization of machinery or equipment during maintenance activities.

What Does Lockout/Tagout Training Involve?

Lockout/Tagout training typically involves classroom instruction as well as hands-on practice with lockout devices such as padlocks and tags. During classroom instruction, workers learn about OSHA regulations pertaining to hazardous energy sources and safe work practices for controlling them. They also learn about specific types of lockout devices available and how to use them correctly in order to isolate a hazardous energy source from its power source. During hands-on practice sessions, workers gain experience in applying lockout devices correctly in order to ensure that they are securely fastened in place before any work can be performed on the machinery or equipment in question.

Who Needs Lockout/Tagout Training?

All employees who work on or near hazardous energy sources must receive lockout/tagout training according to OSHA regulations. This includes maintenance personnel, supervisors, engineers, electricians, machine operators, and other personnel who could potentially come into contact with these sources during their work activities. Additionally, employers must provide refresher courses at least once every three years for all employees who have received lockout/tag out training previously in order to ensure that they remain up-to-date on current safety procedures regarding hazardous energy sources.

How Can Employers Ensure Compliance With Lock Out / Tag Out Training Requirements?

To ensure compliance with OSHA regulations regarding lockout / tag out training requirements, employers should create a comprehensive program that outlines all necessary safety precautions related to working on or near hazardous energy sources such as electrical systems and machines with moving parts. This program should include detailed instructions for identifying potential hazards associated with each type of equipment as well as specific steps that should be taken when performing maintenance activities on it. Additionally, employers should provide regular refresher courses for all employees who have previously received lock out / tag out training in order to keep them up-to-date on current safety procedures related to working with hazardous energy sources. Lock out and tag out training is an essential part of any workplace safety program designed to protect employees from potential harm due to unexpected energization of machinery or equipment during maintenance activities.

What is OSHA Lock Out Tag Out Training?

OSHA Lock Out Tag Out (LOTO) training is a set of safety procedures that are designed to protect workers from the unexpected start up of machinery or equipment. This type of training is mandated by the Occupational Safety and Health Administration (OSHA) in order to ensure that all workers are properly trained in the proper use and maintenance of equipment. The training covers topics such as lockout/tagout devices, energy control procedures, and hazard analysis. It also covers safe work practices for controlling hazardous energy sources, such as electrical, mechanical, hydraulic, pneumatic, chemical, thermal, and other sources.

Why is OSHA Lock Out Tag Out Training Important?

OSHA Lock Out Tag Out training is essential for protecting workers from potential hazards associated with the unexpected start up of machinery or equipment. Without proper training, workers could be seriously injured or even killed if they are not aware of how to safely operate and maintain equipment. Additionally, OSHA requires employers to provide their employees with LOTO training in order to comply with safety regulations.

What Does OSHA Lock Out Tag Out Training Cover?

OSHA Lock Out Tag Out training covers a wide range of topics related to hazardous energy sources and safe work practices for controlling them. These topics include lockout/tagout devices, energy control procedures, hazard analysis, and safe work practices for controlling hazardous energy sources such as electrical, mechanical, hydraulic, pneumatic, chemical, thermal and other sources. Additionally the training covers various types of lockout/tagout devices such as locks and tags; how to identify potential hazards associated with each type; how to properly install each device; how to perform periodic inspections; when it is necessary to use additional protection measures; how to safely remove a device; and more.

Who Should Receive OSHA Lock Out Tag Out Training?

All employees who may be exposed to hazardous energy sources should receive OSHA Lock out Tag out (LOTO) training. This includes anyone who operates or maintains machines or equipment that may contain hazardous energy sources such as electrical circuits or pressurized systems. Additionally supervisors should also receive LOTO training so they can ensure that their employees are properly trained in the use of LOTO devices and procedures.

How Can I Get OSHA Lock out Tag out Training?

There are a variety of ways you can obtain OSHA Lock out Tag out (LOTO) training including online courses offered by many universities or private companies; attending seminars offered by professional organizations; attending on-site trainings provided by employers; or taking part in self-study programs offered by various organizations such as the American Society for Safety Engineers (ASSE). Additionally some employers may offer on-the-job LOTO trainings which can be beneficial for those who need more hands-on experience with using LOTO devices and implementing safety procedures.

Introduction to Lock Out Tag Out Training Certificate Template

Lock out tag out (LOTO) is a safety procedure that is used in the workplace to prevent accidents and injuries. It involves the use of locks, tags, and other devices to ensure that machines and equipment are properly shut off before any maintenance or repair work is performed. A lock out tag out training certificate template can help employers provide employees with the necessary information and instruction on how to safely perform LOTO procedures. The template can also be used to document employee training and demonstrate compliance with safety regulations.

What Is Included in a Lock Out Tag Out Training Certificate Template?

A lock out tag out training certificate template typically includes information about the specific LOTO procedure, such as the type of locks or tags being used, as well as instructions on how to properly perform it. The template will also include a section for documenting when an employee has completed their training and any additional notes or comments that may be necessary. Additionally, the template should include a signature section where employees can sign off on their training completion.

Benefits of Using a Lock Out Tag Out Training Certificate Template

Using a lock out tag out training certificate template offers several benefits to employers. First, it helps ensure that employees receive proper instruction on how to safely perform LOTO procedures. This reduces the risk of accidents in the workplace due to improper use of equipment or machines. Second, it provides employers with an easy way to document employee training and demonstrate compliance with safety regulations. Lastly, using a template makes it easier for employers to track employee progress and monitor their performance over time.

How Can You Create Your Own Lock Out Tag Out Training Certificate Template?

Creating your own lock out tag out training certificate template is relatively simple and only requires basic knowledge of Microsoft Word or other word processing software programs. Begin by creating a new document and adding all necessary sections such as instructions for performing LOTO procedures, signature section for employees, etc. Once you have all sections added you can customize them by adding logos or other images if desired. Finally, save your document as a template so that it can be reused in the future whenever needed.

Conclusion

In conclusion, using a lock out tag out training certificate template can help employers provide employees with proper instruction on how to safely perform LOTO procedures while also ensuring compliance with safety regulations. Creating your own custom template is easy and only requires basic knowledge of Microsoft Word or other word processing software programs. With this in mind, using lock out tag out training certificate templates can be an effective tool for keeping your workplace safe from potential accidents or injuries due to improper use of machines or equipment.

Understanding Lock Out Tag Out Training Requirements Ontario

Lock out tag out (LOTO) training is an important part of workplace safety, and it is required in Ontario workplaces. Understanding the requirements for LOTO training can help employers and employees ensure that their workplaces are safe and compliant with the law.

What Is Lock Out Tag Out Training?

Lock out tag out (LOTO) training is a type of safety training that teaches employees how to safely isolate hazardous energy sources in the workplace. It involves using lock out tag out devices, such as padlocks, to ensure that machinery or equipment cannot be operated while maintenance or repairs are being done. This helps prevent serious injuries or fatalities due to unexpected energization of machinery.

Who Needs Lock Out Tag Out Training?

In Ontario, all workers who may be exposed to hazardous energy sources must receive LOTO training. This includes workers who operate or maintain equipment, as well as workers who may come into contact with hazardous energy sources during their work. Employers must provide this training to all affected workers, regardless of their job title or position.

What Are the Requirements for Lock Out Tag Out Training?

The Ministry of Labour requires employers to provide lock out tag out training that meets certain criteria. The training must include information on how to identify hazardous energy sources, how to use lock out tag out devices, and how to follow proper procedures when isolating machinery or equipment from its power source. The employer must also ensure that the worker receives refresher training on a regular basis, and document that the worker has received the required LOTO training.

What Are the Consequences for Not Complying With Lock Out Tag Out Training Requirements?

If an employer fails to comply with LOTO requirements in Ontario, they can face serious penalties from the Ministry of Labour including fines and jail time. In addition, non-compliance can lead to serious workplace accidents and injuries which can have devastating consequences for both employees and employers alike.

Therefore it is important for employers in Ontario to understand and comply with lock out tag out requirements in order to keep their workplaces safe and compliant with the law.

Lock Out Tag Out Training PowerPoint: What You Need to Know

Lock Out Tag Out (LOTO) is a safety procedure used in workplaces to ensure that hazardous energy sources are properly isolated and controlled during maintenance, servicing, and other activities. It is important for workers to understand the importance of LOTO and how to properly implement the procedure. A Lock Out Tag Out Training PowerPoint can be a great way to educate your staff on the basics of LOTO.

Lock out tag out training powerpoint can provide your employees with an overview of the process, including what it is, why it’s important, and how to properly execute it. The presentation can also provide examples of different types of hazardous energy sources that need to be locked out or tagged out before work begins. Additionally, it can include information on safety protocols that should be followed when working with these sources.

Why Is Lock Out Tag Out Training Important?

It’s essential for all employees who work with hazardous energy sources to understand the importance of Lock Out Tag Out (LOTO) training and how to correctly implement it. Without proper training, workers can be exposed to dangerous situations that could potentially lead to injury or death. LOTO training helps ensure that all personnel are aware of the risks associated with working with hazardous energy sources and know how to safely handle them.

What Should Be Included in a Lockout Tagout Training PowerPoint?

A comprehensive Lockout Tagout Training PowerPoint should include information on:

- The basics of LOTO and why it’s important.

- Different types of hazardous energy sources.

- Safety protocols for working with these sources.

- Proper procedures for locking out or tagging out equipment.

- Emergency procedures if an incident occurs.

Additionally, visuals such as diagrams or photographs can help illustrate key concepts and make the presentation more engaging for your employees.

How Can I Ensure My Employees Are Adequately Trained?

Once you have presented your employees with the Lockout Tagout Training PowerPoint, you should conduct a short quiz or test at the end of the session so you can assess their understanding of the material covered in the presentation. Additionally, you should provide refresher courses periodically so that your employees are kept up-to-date on any changes or updates regarding LOTO procedures. Finally, make sure all personnel are aware of any safety protocols they need to follow when working with hazardous energy sources so they remain safe while on the job.

What is Lock Out Tag Out Training?

Lock out tag out training is a safety procedure designed to prevent workers from being exposed to hazardous conditions, such as electric shock or other potential dangers. It involves the use of specific locks and tags that are placed on equipment or machines to prevent them from being operated until the safety protocols have been followed. Lock out tag out training is an important part of any workplace safety program and is mandated by the Occupational Safety and Health Administration (OSHA) in the United States. Lock out tag out training pdf documents are available for employers and employees to review in order to understand the process better.

Why Is Lock Out Tag Out Training Important?

Lock out tag out training is important because it helps protect workers from unnecessary risks, such as electrocution, explosions, fires, and other hazardous conditions. By understanding how to properly use locks and tags, workers can be sure that they are not inadvertently putting themselves in danger when working with machinery or equipment. Additionally, by following lock out tag out protocols, employers can help protect their employees from liability in case of an accident.

How Does Lock Out Tag Out Training Work?

The lock out tag out process begins with the identification of hazardous energy sources that may be present in a work area. Once these sources have been identified, workers must be trained on how to properly secure them with locks and tags. This includes understanding what type of lock or tag should be used for each source of energy and how it should be securely attached to the machine or equipment. Lock out tag out training pdf documents provide detailed instructions on how this should be done correctly.

What Are The Benefits Of Lock Out Tag Out Training?

By providing lock out tag out training to employees, employers can help ensure that their workers are safe when operating machinery or equipment. This type of training also helps reduce potential liabilities for employers if an accident does occur due to improper use of locks or tags. Additionally, providing this type of safety protocol can help create a culture of safety within a workplace which can lead to greater productivity overall as employees feel secure in their working environment.

Where Can I Find Lock Out Tag Out Training PDF Documents?

There are many resources available online where you can find lockout tagout training pdf documents for both employers and employees alike. These documents provide detailed instructions on how the lockout/tagout process should be implemented correctly so that all parties involved understand what needs to be done for optimal safety in any given work area. Additionally, many websites offer additional resources such as videos and infographics which can help further explain lockout/tagout procedures for those who need more clarification on the topic.

What is Lock Out Tag Out Training in Ontario?

Lock Out Tag Out (LOTO) training is an important safety measure for workers in Ontario, Canada. It is a procedure that helps to ensure that any hazardous energy sources are isolated and locked out before maintenance or repair work on machinery can begin. LOTO training helps to ensure that workers are aware of the risks associated with working on machines and equipment and how to protect themselves from potential harm. By having workers complete LOTO training, employers can reduce the risk of accidents and injuries, as well as minimize the potential for costly property damage.

Why is Lock Out Tag Out Training Important?

Lock out tag out training in Ontario is important because it helps to protect workers from the potential hazards of working on machines and equipment. Without proper training, workers may not be aware of the risks they face when working on machinery or equipment, which could lead to serious injury or even death. Additionally, without proper lockout tagout procedures in place, employers may be liable for any accidents or injuries that occur due to a lack of safety measures.

What Does Lock Out Tag Out Training Involve?

Lockout tagout training typically involves instruction in how to safely isolate and lock out energy sources before performing maintenance or repairs on machines or equipment. Workers will learn about the different types of hazardous energy sources they may encounter, such as electrical, mechanical, hydraulic, pneumatic and chemical energy sources. They will also learn about the different types of locks and tags used for lockout/tagout procedures as well as how to properly use them.

Who Needs Lock Out Tag Out Training?

In Ontario, all workers who perform maintenance or repairs on machinery or equipment must complete lock out tag out training before beginning work. This includes electricians, mechanics, engineers and other tradespeople who work with machines and equipment that contain hazardous energy sources. Additionally, supervisors who oversee these workers must also complete lock out tag out training so they can ensure their employees are properly trained in lockout/tagout procedures.

Where Can I Find Lock Out Tag Out Training?

There are a number of organizations in Ontario that offer lock out tag out training courses for workers and supervisors alike. These courses typically involve both classroom instruction as well as hands-on practice with various types of locks and tags used for lockout/tagout procedures. Additionally, many organizations offer online courses so that workers can take their lock out tag out training at their own pace from any location with an internet connection.

What is Lock Out Tag Out Training?

Lock Out Tag Out (LOTO) training is a type of safety training that is designed to ensure the safety of workers when they are working with hazardous equipment. The purpose of LOTO is to prevent workers from being injured or killed by unexpected start up, release of energy, or the unexpected release of hazardous materials. The LOTO procedure involves identifying and controlling hazardous energy sources, such as electrical, mechanical, hydraulic, pneumatic, chemical, thermal, and other sources. The goal is to make sure that all potential sources of hazardous energy are identified and controlled in order to prevent injury or death.

Why Is Lock Out Tag Out Training Important?

Lock Out Tag Out training is an important part of any workplace safety program. It helps workers understand the risks associated with working on or near hazardous equipment and how to protect themselves from those risks. By providing employees with the knowledge and skills necessary to properly identify and control hazardous energy sources, employers can help reduce the number of injuries and fatalities caused by unexpected start up or release of hazardous materials.

What Does Lock Out Tag Out Online Training Entail?

Lock out tag out online training typically consists of a series of modules that cover topics such as identifying hazardous energy sources, proper lockout/tagout procedures, proper use of lockout/tagout devices, and emergency response plans. The modules also provide information on how to properly document lockout/tagout procedures and provide best practices for maintaining lockout/tagout equipment. Additionally, some courses may include simulations or videos that demonstrate proper lockout/tagout techniques.

Benefits Of Lock Out Tag Out Online Training

One major benefit of Lock out tag out online training is that it can be completed at any time and from any location with an internet connection. This makes it much more convenient than attending traditional classroom-based courses which require employees to be physically present in order to participate in the training. Additionally, online courses can be completed at an individual’s own pace which allows them to learn at their own speed without feeling rushed or overwhelmed by the material being presented. Finally, online courses are often less expensive than traditional classroom-based courses which makes them more cost effective for employers who need to train multiple employees at once.

Conclusion

In conclusion, Lock out tag out online training is an important part of any workplace safety program as it provides employees with the knowledge and skills necessary to properly identify and control hazardous energy sources in order to prevent injury or death. Additionally, online courses are convenient for employers as they can be completed at any time from anywhere with an internet connection and are often less expensive than traditional classroom-based courses which makes them more cost effective for employers who need to train multiple employees at once.

Related products

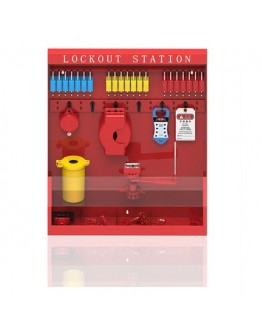

OEM Customized Safety Lockout Station Beian-Lock BAN-X11Enhance workplace safety with the OEM Customized Safety Lockout Station (Beian-Lock BAN-X11). Crafted from durable mild steel in a vibrant red color, this lockout station provides a comprehensive solution for organizing and storing lockout-tagout (LOTO) equipment. With dimensions of 9 x 9 x 3 inches and a weight of 3kgs, it offers a compact yet sturdy design suitable for wall mounting. The station features a clear pocket outside for displaying permit documents, along with an impact-resistant window for easy viewing of items inside. Inside, three hangers with multiple hooks allow for the secure storage of padlocks, while a movable shelf adds versatility. Whether wall-mounted or carried via the built-in handle, this lockout station is ideal for larger group lockout applications, ensuring compliance with safety regulations and promoting a safe working environment.Tailored Solutions for Enhanced Workplace SafetyDurable Mild Steel Construction: Constructed from high-quality mild steel material, this lockout station offers durability and longevity, providing reliable protection for lockout-tagout equipment.Compact Design: With dimensions of 9 x 9 x 3 inches and a weight of 3kgs, the lockout station features a compact and space-saving design suitable for various workplace environments.Vibrant Red Color: The bold red color enhances visibility and serves as a visual indicator of the station's purpose, promoting safety awareness in the workplace.Clear Permit Pocket: Equipped with a clear pocket on the exterior, the station allows for the display of permit documents, ensuring easy access and compliance with safety regulations.Impact-Resistant Window: Features a clear, impact-resistant window that provides a transparent view of all items stored inside the station, allowing for quick inventory checks and inspections.Multiple Padlock Hooks: Includes three hangers inside the station, each equipped with multiple hooks for hanging padlocks, enabling secure storage and organization.Movable Shelf: Incorporates a movable shelf inside the station, offering additional storage space and flexibility to accommodate various lockout-tagout equipment and accessories.Wall-Mounted Design: Designed for easy wall mounting, the station can be securely installed in a convenient location for quick access during lockout procedures.Portable Carrying Handle: Features a built-in carrying handle for portability when the station is not wall-mounted, allowing for easy transportation between different work areas.Suitable for Group Lockout: Designed to lock with several padlocks, the station is ideal for larger group lockout applications, facilitating efficient and organized lockout procedures for enhanced safety...

Add to CartGroup lockout box Beian Lock BAN-X104Enhance workplace safety with the Group Lockout Tagout Box Beian Lock BAN-X104. Crafted from heavy-duty steel and powder-coated for rust resistance, this lockout box ensures secure containment of keys during maintenance operations. Featuring a lockable clasp and a slot for key insertion when locked, it facilitates efficient energy control procedures. With dimensions of 152.4mm x 228.6mm x 88.9mm and a weight of 1329g, it offers ample space for multiple padlocks and keys, promoting exclusive employee control for enhanced safety.Streamline Lockout-Tagout Procedures with Beian Lock BAN-X104 Group BoxRobust Construction: Made of heavy-duty steel and powder-coated for durability, this lockout box withstands harsh industrial environments and provides long-lasting rust resistance, ensuring reliable performance in demanding applications.Secure Locking Mechanism: Equipped with a lockable clasp, this lockout box offers secure containment of keys, preventing unauthorized access to energy control points and enhancing workplace safety during maintenance procedures.Key Slot Design: The inclusion of a slot allows keys to be inserted into the box even when it is locked, facilitating efficient energy control and ensuring accessibility to authorized personnel when needed.Exclusive Employee Control: Designed for use with multiple workers, this lockout box enables each employee to place their own lock on the box, ensuring exclusive control over energy sources and promoting accountability in lockout-tagout (LOTO) procedures.Effective Key Management: By requiring each worker to place their lock on the box containing keys to job locks, this system ensures that keys cannot be accessed until all workers have removed their locks, preventing accidental startup of machinery and equipment.Ample Storage Capacity: With dimensions of 152.4mm x 228.6mm x 88.9mm, this lockout box provides ample space for storing multiple padlocks and keys, accommodating the needs of various lockout scenarios and ensuring comprehensive energy control.Enhanced Visibility: The vibrant red color enhances visibility in industrial environments, making it easy to locate the lockout box and promoting compliance with safety protocols.Versatile Application: Suitable for a wide range of industries, including manufacturing, construction, and utilities, this lockout box offers versatility and adaptability to diverse lockout procedures, ensuring compliance with regulatory requirements and promoting workplace safety...

Add to CartLOTO lockout board Beian Lock BAN-B111Enhance workplace safety with the Beian Lock BAN-B111 LOTO Lockout Board. Crafted from durable mild steel with a powder-coated red finish, this lockout board provides a centralized and organized solution for storing padlocks and lockout devices. With 21 holes to hang padlocks and adjustable hooks, it offers flexibility to suit your specific needs. The two slots at the bottom allow for convenient storage of different types of lockout devices. Wall-mounted for easy access and visibility, this lockout board is an essential tool for effective lockout/tagout procedures.Comprehensive LOTO Lockout BoardDurable Construction: Made from mild steel with a powder-coated red finish, ensuring long-lasting durability and resistance to corrosion.Ample Storage Capacity: Features 21 holes to hang up to 21 padlocks, providing ample storage space for lockout devices.Adjustable Hooks: Hooks can be arranged to accommodate different sizes and configurations of padlocks, offering flexibility to suit your specific requirements.Convenient Organization: Equipped with two slots at the bottom to store various types of lockout devices separately, keeping them organized and easily accessible.Wall-Mounted Design: Designed for easy installation on walls, providing convenient access and visibility of lockout devices for efficient lockout/tagout procedures.Versatile Application: Suitable for use in various industrial settings to enhance workplace safety and compliance with lockout/tagout regulations...

Pre orderPortable Lockout Box BEIAN-LOCK BAN-X04Enhance workplace safety with the BAN-X04 Portable Group Lockout Box, crafted from durable cold-rolled sheet metal for reliable lockout-tagout procedures. Featuring dimensions of 213mm(L) × 116mm(W) × 179mm(H) and a vibrant red color, this lockout box ensures secure management of keys during lockout processes. With a weight of 1100g, it offers portability and convenience for on-site use. Each lockout point allows only one lock, enabling up to 12 or 20 workers to perform lockout procedures concurrently. The innovative design ensures that the box cannot be opened until all padlocks are removed, prioritizing safety in industrial settings.Convenient and Secure Lockout Solution with BAN-X04Durable Construction: Constructed from sturdy cold-rolled sheet metal, providing durability and resilience for long-term use in industrial environments.Compact and Portable: Compact dimensions of 213mm(L) × 116mm(W) × 179mm(H) and a weight of 1100g make it easy to transport and deploy across various lockout points.Secure Lockout System: Each lockout point allows for only one lock, ensuring that multiple workers can perform lockout procedures concurrently while maintaining safety.Key Management: Facilitates efficient key management during lockout procedures, with designated slots for workers to secure their padlocks and keys.Sequential Lock Removal: Features a sequential locking mechanism where workers must remove their padlocks in a specific order to retrieve their keys, enhancing safety protocols.Versatile Capacity: Suitable for accommodating lockout procedures involving up to 12 or 20 workers simultaneously, offering flexibility for different work environments.Tamper-Resistant Design: Designed to prevent unauthorized access and tampering, ensuring the integrity of lockout procedures and worker safety.Compliance Assurance: Helps organizations comply with safety regulations and standards by providing an effective solution for group lockout procedures...

Add to Cart

.png)