Lockout Padlocks

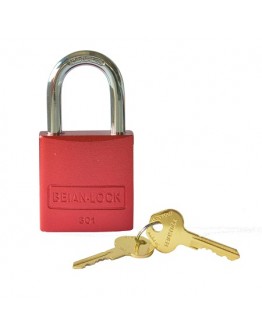

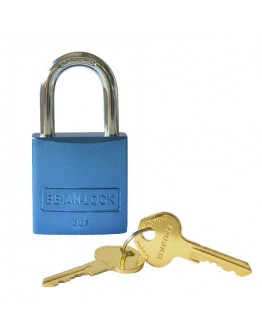

Aluminum Safety Lockout Padlock BEIAN-LOCK BAN-301Lockout Tagout Home Aluminum Safety Padlock 301 is a high-quality, aluminum-based lock-out/tag-out (LOTO) padlock designed for use in both industrial and domestic settings. The purpose of a LOTO padlock is to isolate energy sources, such as electrical switches or valve handles, during maintenance, repairs, or other activities, providing a higher level of safety and accountability.Lockout Tagout Home Aluminum Safety Padlocks 301 is made of lightwe..

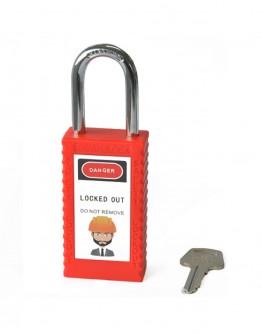

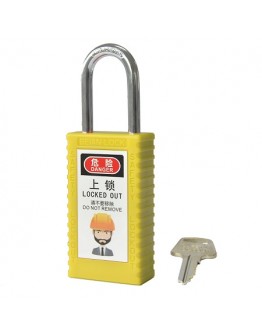

Add to CartLockout LOTO Padlock With Safety Dielectric Nylon Shackle BEIAN-LOCK BAN-202Ensure reliable lockout/tagout procedures with the Lockout LOTO Padlock With Safety Dielectric Nylon Shackle BEIAN-LOCK BAN-202. Crafted with imported Dupont Nylon material, this padlock meets OSHA1910.147 regulations, offering superior safety in industrial environments. The robust nylon shackle, available in a height of 38mm, has passed tensile tests for durability and reliability. Featuring an all-brass cylin..

Add to CartLong Body Lockout Lock BEIAN-LOCK BAN-501Ensure optimal security and durability with the Beian-Lock BAN-501 Long Body Lockout Lock. Crafted from stainless steel, this lock boasts a sturdy construction and features a durable, lightweight, and insulated Xenoy® material lock body. With a 6mm diameter metal shackle and options for 38mm or 76mm shackle height, this lock offers versatile use for various applications. Its key retaining feature and specially designed double slot key meet multi-level man..

Add to CartLong Shackle Lockout Lock BEIAN-LOCK BAN-211LEnhance your lockout/tagout procedures with the Beian-Lock BAN-211L Long Shackle Lockout Lock. Crafted from imported Dupont Nylon and steel, this lock features a durable, lightweight, and insulated Xenoy® material lock body with a 6mm diameter shackle. With a 76mm steel shackle height and options for KD/KA/MK or KAMK configurations, this lock offers versatile security solutions for various industrial applications.Long Shackle Lockout Lock for Enhanced..

Add to CartLockout Tagout Padlock LOTO With Steel Long Shackle BEIAN-LOCK BAN-201LEnsure optimal security with the Beian Lock BAN-201L LOTO Safety Lockout Padlock. Crafted from durable imported Dupont nylon and steel, this padlock features a 6.3mm diameter steel shackle with a 76mm height, providing enhanced security and resistance to tampering. The lock body is made of lightweight and insulated Xenoy® material, offering durability and protection against extreme temperatures, chemicals, and UV ra..

Add to CartLoto Padlock Lockout with Steel Shackle 4mm BEIAN-LOCK BAN-701Enhance security with the Beian Lock BAN-701 Loto Padlock Lockout. Crafted from durable nylon and fiber, this padlock features a 4mm thin shackle with a 38mm height, offering versatile locking options for various industrial applications. Available in both nylon - non-conductive lockout padlock and steel materials, the shackle provides flexibility to suit specific security needs. With a strong key retaining feature, the..

Add to CartLOTO Safety Lockout Padlock with Steel Shackle for Industrial Safety BEIAN-LOCK BAN-S01Ensure industrial safety with the Beian Lock BAN-S01 LOTO Safety lockout padlock keyed different. Crafted from durable nylon and fiber, this padlock features a 4.5mm diameter shackle with a 28mm height, offering reliable security for a variety of applications. Designed for marine, outdoor, and small aperture use, these safety locks are made of Imported Dupont Nylon material, ensuring durability and resist..

Add to CartLOTO Safety Nylon Non-conductive Lockout Padlock for Industrial Safety BEIAN-LOCK 202LEnhance industrial safety with the Beian Lock 202L LOTO Safety Nylon Non-conductive Padlock. Crafted from Imported Dupont Nylon material, this padlock features a 6.3mm diameter nylon shackle with a 76mm height, providing reliable security for various industrial applications. Compliant with OSHA regulations, this padlock follows the "one employee, one lock, one key" directive, ensuring workplace safety. With a s..

Add to CartDurable and Electrical-Safe: Industrial Nylon Insulated Safety Lockout Padlock BEIAN-LOCK BAN-S02The S02 Industrial Nylon Insulated Non-conductive Lockout Padlock are a premium lock solution for high-risk industrial environments. Featuring a sturdy nylon body and an insulated design, this lock protects against electrical hazards while also providing strength and durability. The shackle is made from hardened steel, making it resistant to cutting and sawing. With a simple, easy-to-use design, this..

Add to CartSteel Shackle LOTO Safety Lockout Padlock BEIAN-LOCK BAN-201Enhance workplace safety with Beian Lock Steel Shackle LOTO Safety Lockout Padlock BAN-201. Constructed from durable Nylon+Fiber material, this safety padlock meets OSHA1910.147 regulations and features a 6.3mm diameter, 38mm height shackle, and a robust thermoplastic body. With dimensions of 46*23.5*95.4mm and weighing 120g, it offers reliability and security for lockout/tagout procedures. The padlock complies with the "one e..

Add to CartWaterproof and Dustproof Rubber Sleeve for Safety Padlock GSTA11. Suitable for a rainy day, or dust environment for safety padlocks.2. DP stands for dustproof...

Add to CartLockout Padlock are one of the most important component of the lockout process. Securing equipment is the top priority during lockout and padlocks ensure added safety by preventing the powering, use, or movement of the equipment that's locked out. Available in a wide range of sizes and colors, as well as specialty models such as dielectric padlocks, plastic padlocks and single use padlocks. Padlocks effectively prevent tampering and reduce the chance of injury, accident or damage to sensitive equipment and machinery. Browse our complete selection of padlocks below.

Lockout Padlocks are an important safety measure for industrial workplaces where hazardous

equipment and machinery are in use. A lockout lock is a device that is used to

physically secure a switch, valve, or any other energy-isolating device in

order to prevent the release of hazardous energy. A lockout padlock is a type

of lockout lock that is used to secure a specific area or piece of equipment,

preventing unauthorized access or use.

The use of

lockout padlocks and lockout padlocks is a critical component of a comprehensive

lockout/tagout (LOTO) program, which is designed to protect workers from

serious injury or death that can occur as a result of hazardous energy

releases. The Occupational Safety and Health Administration (OSHA) requires

that employers implement a LOTO program in order to ensure the safety of

employees who work with hazardous energy sources.

Lockout padlocks and lockout padlocks come in a variety of styles and materials to suit

different needs and applications. They can be made of durable materials such as

metal or plastic and can be used in combination with other lockout devices,

such as hasps, cables, or tags, to provide added security and versatility. Some

lockout padlocks and lockout padlocks even come with special features such as

multiple lock holes, keyed-alike options, and key retention to prevent

accidental removal.

One of the

key benefits of using lockout padlocks and lockout padlocks is that they provide a

visual warning to others that the equipment or machinery is being maintained or

repaired, and that it is not to be used. This helps to eliminate the risk of

accidental activation, and ensures that only authorized personnel can access

the equipment.

Another

important aspect of lockout padlocks and lockout padlocks is that they provide a

secure method for locking out equipment, as opposed to other methods such as

tying a rope or using a piece of tape. These methods may not be reliable, and

can easily be removed or broken, allowing unauthorized access to the equipment.

With a lockout lock or lockout padlock, the equipment is secured with a

physical barrier that cannot be easily bypassed.

In order to

ensure the effective use of lockout padlocks and lockout padlocks, it is important

for employers to provide proper training for employees on the proper use and

maintenance of these devices. Workers should also be made aware of the

importance of using lockout padlocks and lockout padlocks, and understand the

consequences of not following established LOTO procedures.

In

conclusion, lockout padlocks and lockout padlocks are a vital component of a

comprehensive lockout/tagout program, and are essential for ensuring the safety

of workers in industrial workplaces. With proper use and maintenance, these

devices can provide a secure and reliable method for controlling hazardous

energy sources, and help to prevent serious injury or death in the workplace.

.png)