Industrial Safety Lockout

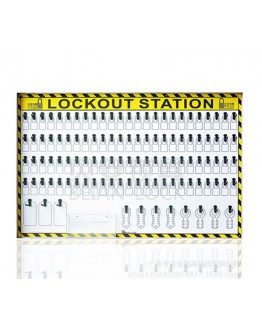

Lockout Board BAN-B08-1Ensure workplace safety with the Lockout Board BAN-B08-1, a high-visibility lockout station designed for storing isolation locks and equipment. Strategically placing this lockout station near isolation points encourages workers to adhere to proper isolation procedures, enhancing overall safety protocols. Crafted from durable PPC material, the board features prominent black and yellow chevrons along the outer edge for enhanced visibility. Easily mountable on walls, this loc..

Pre orderLockout Board BAN-B08-2Enhance workplace safety with the Lockout Board BAN-B08-2, a high-visibility lockout station designed to promote proper isolation procedures. Crafted from durable PPC material and featuring prominent black and yellow chevrons along the outer edge, this board ensures maximum visibility in any environment. Easily mountable on walls, it provides a convenient and accessible solution for organizing lockout/tagout equipment, making it an essential addition to any industrial sett..

Pre orderLockout Board BAN-B08-3Ensure workplace safety and compliance with the Lockout Board BAN-B08-3, a high-visibility lockout station designed to enhance isolation procedures. Crafted from durable PPC material and featuring prominent black and yellow chevrons along the outer edge, this board offers maximum visibility in any environment. Simple to mount on walls, it provides a convenient and accessible solution for organizing lockout/tagout equipment, making it indispensable for industrial settings.O..

Pre orderLockout Board BAN-B08-4Enhance workplace safety and organization with the Lockout Board BAN-B08-4, a high-visibility solution for storing lockout/tagout equipment. Crafted from durable PPC material and featuring bold black and yellow chevrons along the outer edge, this board ensures easy identification and maximized visibility. With effortless wall-mounting capability and spacious dimensions of 660mm x 520mm, it provides a convenient and accessible storage solution for isolation locks and device..

Pre orderLockout Board BAN-B08-5Maximize workplace safety and organization with the Lockout Board BAN-B08-5, a highly visible storage solution for lockout/tagout equipment. Crafted from durable PPC material and featuring bold black and yellow chevrons along the outer edge, this board ensures easy identification and enhanced visibility in industrial environments. With effortless wall-mounting capability and generous dimensions of 800mm x 650mm, it offers ample space for organizing and storing isolation lo..

Pre orderLockout Board BAN-B08-6Elevate workplace safety and organization with the Lockout Board BAN-B08-6, a prominent storage solution designed for lockout/tagout equipment. Crafted from durable PPC material and adorned with striking black and yellow chevrons along the outer edge, this board ensures easy identification and heightened visibility in industrial environments. With effortless wall-mounting capability and generous dimensions of 1220mm x 800mm, it provides ample space for organizing and stori..

Pre orderLockout Board BAN-B08-7Elevate workplace safety and organization with the Lockout Board BAN-B08-7, a robust storage solution designed to enhance lockout/tagout procedures. Crafted from durable PPC material and accented with prominent black and yellow chevrons along the outer edge, this board ensures optimal visibility and easy identification in industrial settings. With effortless wall-mounting capability and spacious dimensions of 1220mm x 800mm, it provides ample space for organizing and stori..

Pre orderLockout Station BAN-B103Enhance workplace safety with the Lockout Station BAN-B103, a covered station designed for storing safety padlocks and devices. Unfilled for customization, this large-capacity station accommodates a variety of lockout devices tailored to your specific lockout needs. Featuring trilingual labeling in English, Spanish, and French, it ensures clear communication across diverse work environments. Crafted from resilient polycarbonate material, this station offers superior heat..

Pre orderLockout Station BAN-B104Streamline lockout procedures with the Lockout Station BAN-B104, featuring a deluxe tag center for comprehensive organization of lockout tags and accessories. Constructed from durable polycarbonate material in yellow, this station offers enhanced visibility and durability for industrial environments. Weighing 2,720g, it provides a sturdy and reliable solution for lockout management. The deluxe tag center includes two tip-out bins, each with three compartments for storing ..

Pre orderLockout Station BAN-B112Enhance your lockout procedures with the Lockout Station BAN-B112, featuring a double-sided composite aluminum construction for durability and versatility. Crafted from fully traceable aluminum composite, this station is free from recycled content, cadmium, or lead, ensuring superior quality and safety. Its brilliant white anti-fade lacquer-style finish offers a professional appearance while providing resistance to moisture ingress. The high-strength magnetic surface is e..

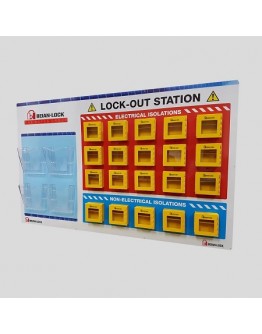

Pre orderLockout Station Beian Lock BAN-B106Optimize your lockout procedures with the Beian Lock BAN-B106 Lockout Station, designed for enhanced safety and convenience. Constructed from durable mild steel with a heavy-duty powder coating in vibrant red, this station withstands outdoor elements and provides superior corrosion resistance. Wall-mounted for easy accessibility, it features clear visible windows for effortless viewing of permits and keys during lockout situations. The included lock caddy facil..

Pre order

.png)